EU manufacturers are increasingly embracing digital technologies to improve agility.

By HELEN MASSY-BERESFORD

A plant that makes electric shavers in the northern Dutch town of Drachten is gearing up for a test meant to help European industry thrive in increasingly competitive international markets.

The plant run by consumer-electronics company Philips is part of a research project that received funding from the EU to spur manufacturers to make use of “digital twins” – virtual factories created through technologies that promise to streamline actual production.

Virtual and real

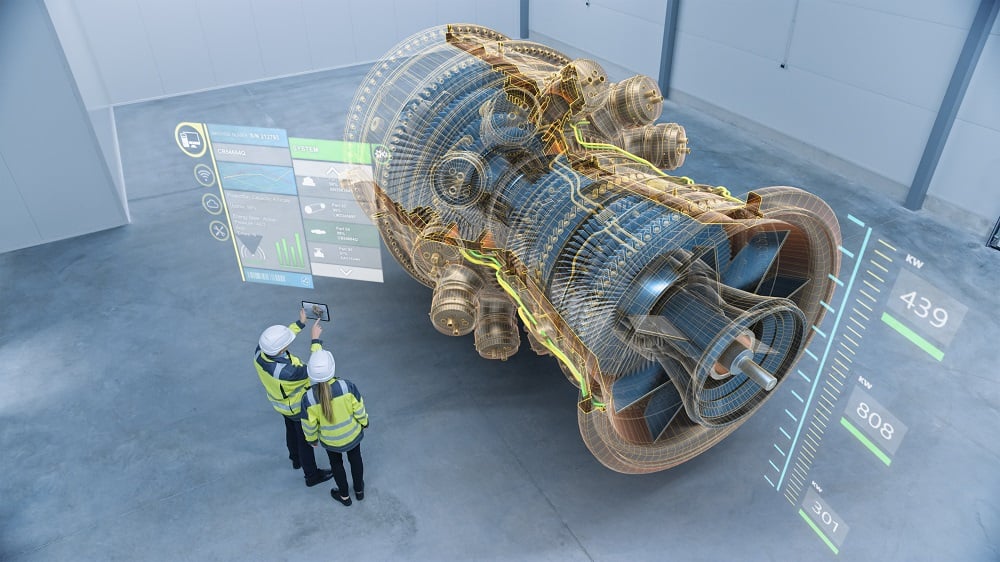

The idea is to harness techniques such as cloud computing, artificial intelligence, robotics and blockchain technology to create models of whole manufacturing processes and pinpoint where improvements can be made.

‘Industry is in a transition phase and digital technologies can help,’ said Dr Cécile Girardot, coordinator of the DIMOFAC initiative running through March 2024. ‘With digital twins, real-time data can show in the virtual world how machines are performing in the real one.’

Europe’s €5 billion manufacturing sector, which includes global heavyweights in areas ranging from aviation and steel to cars and chemicals, faces export-minded producers abroad and tougher environmental rules at home.

To these two underlying challenges have been added energy-price spikes following Russia’s invasion of Ukraine in February 2022 and supply-chain disruptions caused by the Covid-19 pandemic that struck two years earlier.

The EU has created a €1.15 billion public-private partnership called Factories of the Future to advance manufacturing research and innovation, signalling how high the issue is on the European policy agenda.

At stake is European companies’ ability to navigate through what is widely called the Fourth Industrial Revolution, or “Industry 4.0”, an age marked by automation and connectivity.

The virtual-factory idea is gaining ground in Europe. Manufacturers ranging from aircraft maker Airbus to electrical equipment specialist Schneider Electric are exploring digital-twin concepts and setting up virtual manufacturing facilities.

Plug and produce

DIMOFAC, which began in late 2019, has developed a system to make manufacturing more agile.

Called “Plug and Produce”, it renders reconfiguring production lines easier by linking real machines with digital twins.

Using the system, a manufacturer could simulate a new set-up virtually and iron out any troubles online before installing the equipment in an actual factory.

Production problems can arise, for example, from using recycled raw materials because their properties aren’t always identical, according to Girardot, who is European project coordinator in advanced materials and manufacturing at French research institute CEA-Liten.

‘In this case you have to adapt your production,’ she said. ‘The faster you do that, the better it is. The main objective is to reduce reconfiguration times.’

The project’s “Plug and Produce” system will be tested in five actual production facilities around Europe. Besides electric shavers in the Netherlands, examples include aerospace components made by Éirecomposites in Ireland and interactive displays produced by Schaltag in Switzerland.

The technology is being put in place at the five sites and results are due during the first quarter of 2024.

DIMOFAC has been able to draw on a wide range of industrial expertise through 30 partners that also include Siemens Industry Software (France), mechanical-engineering company FILL of Austria and EXOM Engineering in Spain.

Closer collaboration

Another EU-funded project to advance the prospect of digital factories, FIRST, explored how they could be used to increase efficiency at production sites spread across different locations.

New designs and processes developed by FIRST will facilitate collaboration, according to Lai Xu, who coordinated the initiative that ended in December 2022 after six years.

‘Traditionally, manufacturing sites can be quite isolated,’ said Xu, an associate professor at Bournemouth University in the UK who works on collaborative business processes and virtual enterprises.

FIRST set out to identify the challenges and obstacles in the way of using virtual factory technologies and develop ways to overcome them, according to Xu.

The project’s partners numbered seven and included manufacturers, software companies and universities from countries including Germany, Italy, the Netherlands and China.

Xu is upbeat about what digital twins can offer industry on both the business and environmental fronts.

For example, using a digital model of the whole production process, a fashion company could design a pair of shoes in Paris or Milan while coordinating manufacturing and sales globally.

An information-technology network would connect all the partners – shops, designers, logistics and manufacturers – and send information about what is needed where and when using blockchain technology.

‘The customised shoe can be designed elsewhere but made locally, resulting in a more efficient and flexible manufacturing process and with less environmental impact,’ Xu said.

A la carte

Virtual-factory technologies aren’t all or nothing. Manufacturers can embrace parts to improve processes without committing to the whole, according to Xu.

This could be an important consideration for the many small and medium-sized enterprises that are part of Europe’s manufacturing sector and that may lack the resources to revamp their systems from A to Z.

Virtual-factory technologies can also help companies more efficiently manage the maintenance of complex machines, saving costs as a result.

‘Sensors around the machine collect data allowing you to schedule when to fly an engineer out for service,’ said Xu.

In a sign that virtual manufacturing technologies are set to become increasingly important, she said the FIRST consortium is actively seeking new EU and national funding to make further advances in the field.

Research in this article was funded by the EU.

More info

This article was originally published in Horizon, the EU Research and Innovation Magazine.